Exciting Disruptions Coming For Architects, Engineers, and Contractors

With advancements in generative design, software algorithms, and robotic construction, our current processes are going to be changing quite a bit over the next three to five years. We will see more and more done by computers and machines than we have ever seen.

Rather than Building Information Modeling (BIM), we are going to see Building Information Optimization. Rather than manually drawing walls, doors, and columns for what we think is a good design, we will feed the computer “rules” instructing it to give us a building’s optimal footprint, structural load capacity, and thermal performance. Things that took months will be done in a day. What does this mean for you? How do you play a part in these changing processes?

In his book, Rise of the Robots: Technology and the Threat of a Jobless Future, Martin Ford discusses how software algorithms and robots will be replacing lower paying jobs such as fast food attendants as well as higher paying jobs such as writers and legal professionals. What patterns are you seeing in your own industry? What place might robots and algorithms eventually have in the office and in the field?

The movie I, Robot raises the question, “Can a robot write a symphony? Can a robot turn a canvas into a beautiful masterpiece?”

In a Slate.com article, Chris Wilson states, “Cope has been writing software to help him compose music for 30 years, and he long ago reached the point where most people can’t tell the difference between real Bach and the Bach-like compositions his computer can produce. Audiences have been moved to tears by melodies created by algorithms.”

Pindar Van Arman, a technology artist, and software engineer, has built a robot that can paint art. Van Arman, who is an avid painter himself, first built the robot as an assistant for his personal projects. Now the robot can make beautiful portraits and landscapes, either with the assistance of a human or entirely on its own.

Here’s a question for all of us: Can an algorithm design a building? Can a robot construct a structure?

Where We Have Been

Most firms currently using BIM software are focused on gathering data. We design buildings manually, enter data manually and then print data manually. This system works for the most part; however, it’s not very efficient. (By the way, most firms are not even executing this process very well. Most firms are using their BIM software like it’s a CAD program.)

How does design happen at your office? Is the design typically modeled in a static design software like Sketchup? Of course, the nice thing about conceptual modeling software is that you don’t have to think as much about assemblies, materiality, etc.

What if we could make multiple design iterations in a conceptual tool without having to remodel our buildings every time there was a change? The most obvious advantage is the efficiency of not having to remodel over and over again. We can create multiple iterations very efficiently.

FormIt is another conceptual modeling tool. One nice advantage about FormIt is the ability to plug and play with Dynamo (pun intended).

In the future, rather than gathering data and reporting on that data, we will use data to inform our designs. We can use Parametricism plus BIM to help us problem solve. Below is an example of when I first started learning how to use data driven design. One of the challenges I had with this specific design was to rationalize the radius such that the panels would divide evenly and stay planar for the fabricator. The way I problem solved this was thinking rational form=rational panels. Using data and math I was able to achieve this goal; however, the family was rigid and not intuitive to edit.

Where We are Now

I later started getting into algorithmic editors like Grasshopper and Dynamo.

Here is the same example; however, notice how easy it is to edit the geometry, and I can constrain the panels and keep them planar! As tools become easier to use, we will see a wider adoption rate.

The Cost of Machines Versus Humans

Using technologies like CNC (Computer Numerical Control). This means a computer converts the design produced by Computer Aided Design software (CAD), into numbers. The numbers can be the coordinates of a graph and they control the movement of the cutter.

In the past, if we asked a human to cut these beams, the price would have been more expensive given the complexity of the templates and the form. However, if we are using a CNC to cut straight beams or curved beams, the price is the same. But what happens to the job of the traditional fabricator? Does the machine replace him? No. He now operates and maintains the machinery. The machine and the craftsman become an integrated team.

Interoperability

What design tools do you use? If you are like most firms, you are likely designing in Sketchup, and maybe a little bit of FormIt or Rhino. What happens when you get to design development? Are you recreating the model that was in Sketchup in Revit now? Notice the data drop? What if you could hit a button and it would translate your model from Sketchup/Rhino to Revit?

To learn more about this process you can check out my tutorials on Pushing Grasshopper to Revit or Crossing The Model Drop Chasm.

In the future, we will not spend months translating information from one software to another software. I envision in the future, the cloud will be software agnostic, and we will be able to create, manipulate, and capture information regardless of what software the geometry was created in. Keep a watch out for Quantum.

Where We Are Going

AI (Artificial Intelligence) BIM

This is where it gets exciting…computers will be able to be fed a set of tasks, rules, and processes and be able to execute them autonomously and more efficiently than humans.

AI BIM Plus Task Automation

We see hints of AI BIM today. Do you enjoy manually creating PDFs, exporting DWG files, and detaching Revit models? In the very near future, you won’t. This is available now. IMAGINIT’s product clarity automates tasks such as printing, publishing to Navisworks, and creating room data sheets. The ROI is ridiculous.

Imagine if the computer knew when milestones were, when the model changed, and being able to react by exporting the information for the consultants. Take it another step further. What if all modeling was done in the cloud, and you had live PDF sets. Every time a change happened, your PDF updated in real time. It’s not that hard to imagine given where we are today.

AI BIM Plus 3D Coordination

The traditional 3D coordination/clash detection process is about to get an overhaul. Building System Planning, Inc., has an Auto Route Feature tool called “GenMEP” (Generative Design MEP). Imagine a tool that routes ductwork and piping while being object aware and missing the Beams and other MEP information. Currently the user tells the tool which pieces to connect, and it routes missing the structural/MEP information. Rather imagine feeding the computer the load requirements, room types, etc., and the computer algorithm autonomously designing, routing, and modeling the MEP information. What will be the time saved during the 3D coordination process when the GC is involved? What happens when the subs have this same technology? I think we will see this technology within the next three years.

AI BIM Plus Analysis and Design

Manual analysis and modeling is going away. GRAITEC Advance BIM Designer Collection has already created a tool that is a design-driven reinforcement calculation program for 3D cage modeling and automates documentation production for reinforced concrete columns, beams, and footings. It’s just a matter of time before this tool becomes mainstream.

Imagine in the next five to ten years, structural analysis having a more direct influence on architectural design. It already does today, but with advances in material science, biomaterials, and algorithmic modeling, we could see extremely efficient structural buildings with half the material.

AI BIM Plus Architecture

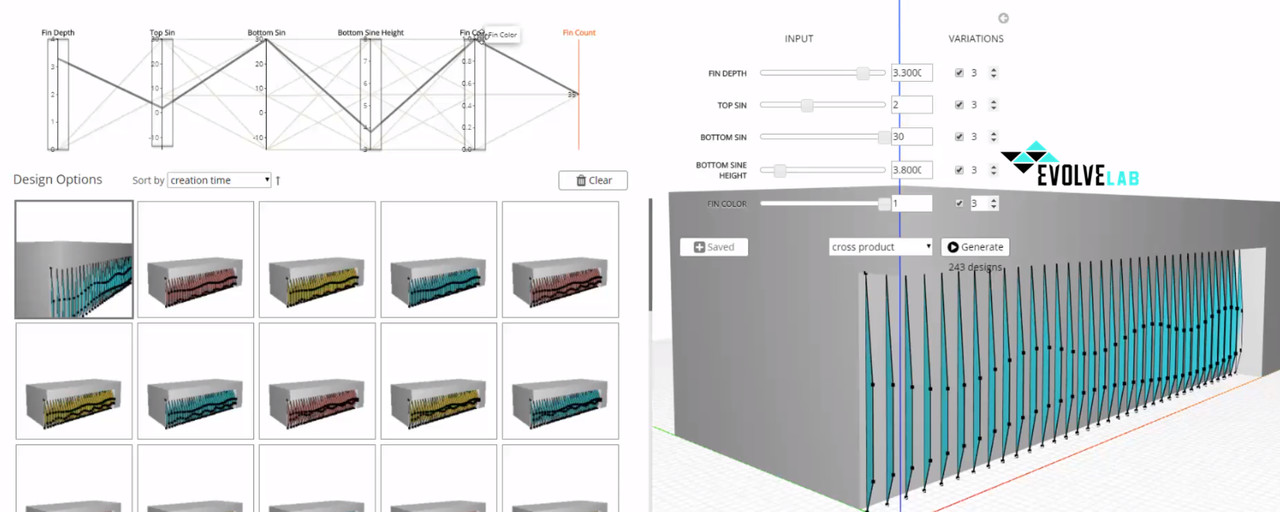

The ability to execute generative design is becoming more and more possible. With the ability to be able to publish Dynamo to the web interface Fractal, and have a computer generate thousands of design iterations is going to disrupt the way we think about design.

If you are interested in learning more about this technology, you can check out my class FormIt To Fractal - The Future Of Making Things Is Here

AR/VR

You can’t talk about the future of our industry without touching on VR/AR. In the future, we will not have to choose between virtual reality and mixed reality headsets. The headsets of the future will have lenses that will be able to accommodate both virtual reality and mixed reality.

Additionally, as the hardware becomes lighter and more comfortable, we will wear them throughout the day and not only when we want to see a rendering. Expect to see hybrid VR/AR headset within two years. With additional accessories that allow us to experience pressure, temperature and smells, it will be much harder to decipher the virtual from the actual.

The goal of most VR headsets is to make yourself look like an idiot while swinging a sweaty remote control and headset around.... Nailed it...

How Will Robots Drastically Change the Construction Industry?

Will the robots of the construction industry look like the robots of the food industry? I believe robots of the future will look more like machinery than they do people.

Robots certainly can’t do a lot of the same tasks that humans do such as navigating a construction site, right? Uber has invested heavily in self-driving cars that navigate city streets with pedestrians and other civilians in their own vehicles. These self-driving cars have object avoidance algorithms that are fed information from sensors mounted to the vehicle. It is only a matter of time before robots are working side-by-side with construction workers.

Robots are already showing up in construction. Below is a robot that is helping pavers lay pavers more efficiently (and save their backs/knees).

The workers feed the bricks to the top of the robot, and the machine robot lays the bricks in the desired pattern.

Arch_Tec_Lab is a test facility for Robotic Fabrication in Architecture located in Zurich, Switzerland. The facility is currently prototyping robots and their use in construction. The thought behind the facility is to not be limited by a two-way path similar to auto construction, but rather be completely free to assemble complex forms using the 40-axis of movement of the robotic array.

SAM, (Semi-Automated Mason) is a robot designed to make construction work a more efficient process. Costing half a million dollars, its creators claim that SAM can lay between 800 to 1,200 bricks in a single day — a skilled human mason tends to top out at 500.

Hadrian line of bricklayer robots claims that their robot can lay 1,000 bricks per hour!

3D printers are now leaving the office and building on-site to scale. With the advent of 3D printing and material science, we are going to see more unique buildings in lieu of the traditional boxes. This is because from a labor standpoint it will not cost any more to build a rectangle than an oval.

The Internet of Things

If you combine robotics, construction, and the Internet of Things (IoT), this is where it gets exciting. Like the Uber car never running into other objects, imagine if drones and machinery were object aware and could not run into humans.

Architect Ammar Mirjan programmed together a small collection of drones to fly hundreds of blocks into a formation to build a six-meter-tall tower. It was a first for drones.

All in all, robots are drastically faster than humans and they never get tired or injured. They will never file a worker’s compensation claim. Construction accounts for one-fifth of all U.S. worker deaths on the job. This is only in the U.S.! In 2014 the government counted 870 construction workers dead.

How can you best prepare yourself and your firm for these changing processes? Check out our blog at evolvebim.com/blog or become a member at evolvebim.com/membership and download some of the free resources.

If you have enjoyed this article, please share it with your friends and colleagues.

Technical Director. Technical Excellence Lead (Metros & Civil Division) at Mott MacDonald

6yCongratulations for the article. It is very impressive the amount of tools and opportunities that existing software offers even now. Although it seems as a general true that technology already in use in aerospace or automotive industries will arrive to contruction is not clear how considering particularities and benefit margin obtained. Also, risk management and safety an unknown. Who and when takes responsability of the result. The user? The manufactorer? The client? No matter if finally a black box will do everything behind the scenes you need someone who know what is going on. Accountability will be discussion and hope for the value of human factor.

SaaS/Low & no-code commercial expert. Initiator of Saas Growth Collective & Sportbuddy

6yWouter Riedijk

Founder/CEO @ Structure Pal Ltd | AI-based AEC optimization solutions

6yGreat Article! thanks!

Co-Founder, Head of Product at Wishkarma

6yIndeed

I do not know if I should smile or cry!!